Making minimal access surgery available to everyone

MedTech Automation

Minimal Access Surgery (MAS), where surgical procedures can be carried out via small incisions in the body as opposed to larger “open” ones, is widely acknowledged to be the preferred treatment option for patients undergoing surgery, when possible to do so.

MAS is far less invasive to patients, so causes less trauma to the body and recovery times are greatly reduced. Incidences of complications post op are low too.

So if MAS could be deployed more widely and the benefits are considerable, not least in reduction of bed capacity and faster return to work, there could be significant benefits to healthcare systems and society at large. As we usher in an age where sustainability is so closely linked with productivity these are very relevant considerations.

However, MAS can be extremely mentally and physically challenging for a surgeon to perform which means that many patients who are suitable for minimally invasive surgery are still getting an open procedure.

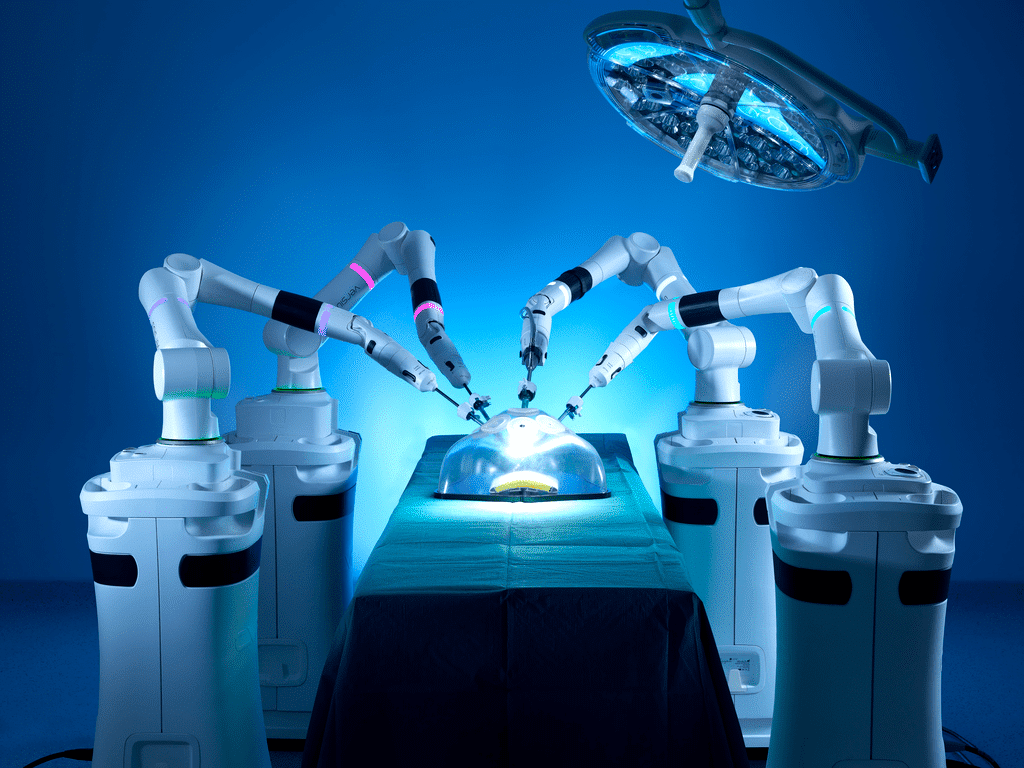

Now, thanks to advances in Robotically Assisted Surgery (RAS) an increase in the number of minimally invasive procedures is possible. And RAS also delivers whole new dimensions to modern surgery which go way beyond broadening the scope of MAS.

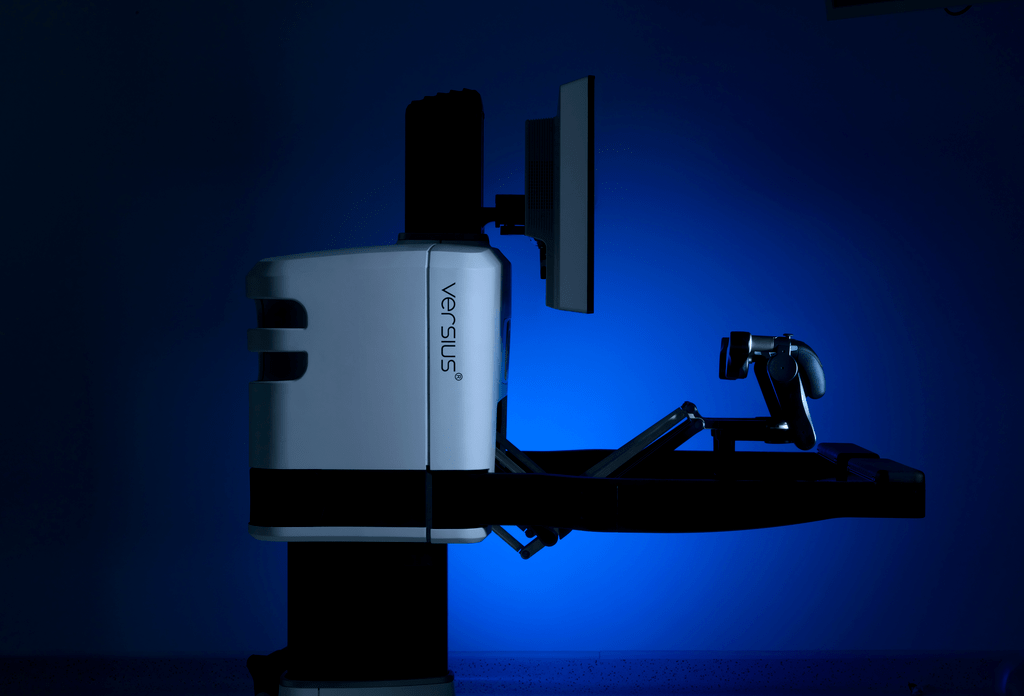

Use of robotic interfaces provides the surgeon with ergonomic benefits as they sit at a console with a 3D screen rather than standing-sometimes for multiple hours-at the operating table. This has the potential to have a significant impact on their wellbeing. In fact 20% of UK surgeons regularly performing MAS reported they have to retire early due to the physical impact of their work.

And data. Put simply, the more of one procedure a surgeon performs, the better they become at it. Input telemetry from thousands of different surgeons into a single point and you’ve vastly enhanced data with ground-breaking potential. So the stage is very much set for a RAS revolution. There’s one snag however. Surgical robots are extremely complex medical devices. This means that hospitals need to invest into training teams and in the system itself.

Now there’s a solution. Versius from CMR Surgical.

Driven by their mission to “make the benefits of minimal access surgery available to everyone who needs it” CMR Surgical exists to make robotic assisted surgery more accessible and affordable around the world.

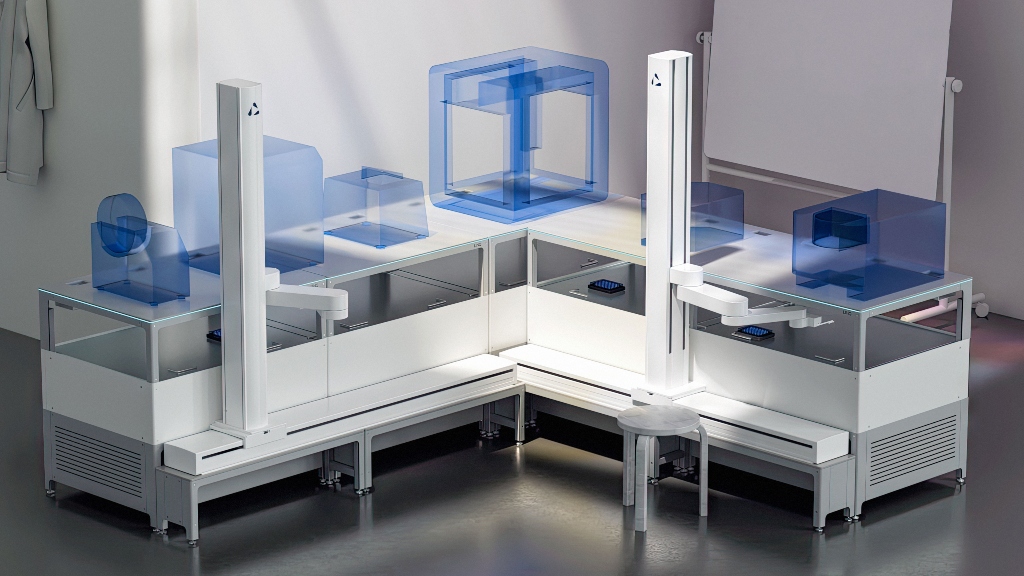

Its surgical robot, Versius, is uniquely small and modular allowing it to be deployed in virtually any hospital and moved between departments to maximise its utilisation between various surgical specialties.

With Versius surgeons can can operate with fully-wristed instruments and enhanced 3D vision. This allows the surgeon to mimic their own human movement, allowing for more precise surgeries while also making long procedures less strenuous.

Versius is also part of a wider digital ecosystem which makes surgical data actionable and meaningful so that surgeons can make better informed decisions to improve patient care while maximising efficiencies. This can also help standardise surgery and support surgeons’ continuous learning.

The global surgical community has been quick to adopt Versius which has made CMR the fastest growing surgical robotics company today. With adoption levels high, CMR Surgical needed a manufacturing partner to support them to scale.

Enter Tharsus- making what you need now.

We’re unique in that through our Solve Scale Supply service offer, we’re an advanced manufacturer like no other.

Solve offers our extensive technical experience of resolving design for manufacture in first of kind products to make your tech more efficient, while scale and supply support your product’s manufacturing needs as your market demand requires.

Embedded in this is our ability to bring increased efficiency and therefore drive decreased cost into the whole process which increases scalability and enhances commercial success and ROI for our customers.

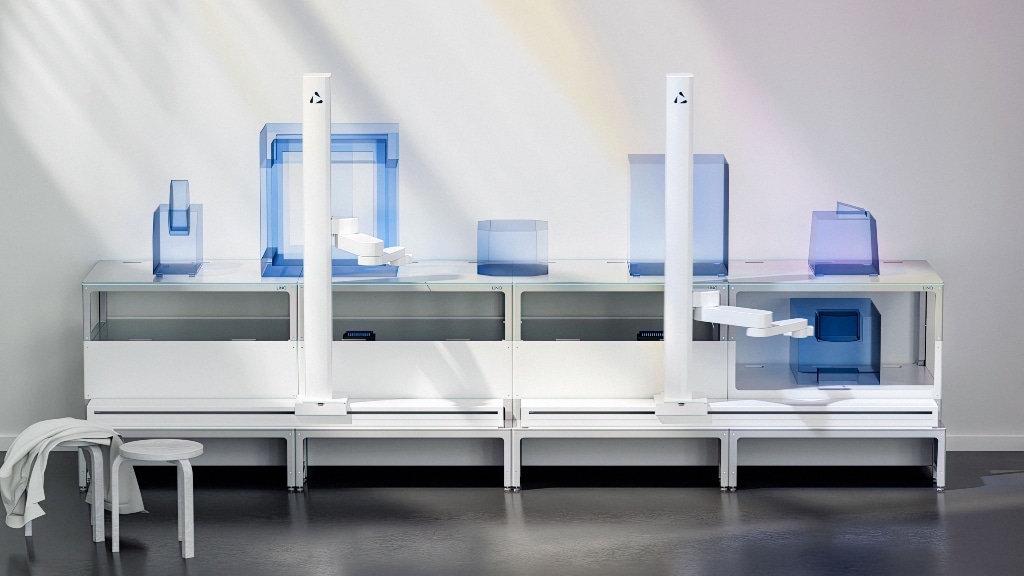

With the global roll out of Versius front of mind, CMR Surgical came to us in 2020 to be a manufacturing partner for the surgeon console element of Versius, and a close collaborative partnership began which has seen us support hundreds of Versius systems to successful completion and deployment, with production virtually tripling along the way.

Working with CMR Surgical has been a period of growth for Tharsus which goes way beyond manufacturing, however.

Given the sector we’re working in there are extremely high standards of control, documentation and certification which have to be stringently kept to. Doing this while maintaining the manufacturing flexibility which brought CMR Surgical to us originally has led us to build a quality management resource around the build which goes way beyond the already high bar we set for our customers’ products. The margin for error is zero. And in manufacturing terms that’s no small feat.

And we’ve grown in our mission, too. It’s very important to us to deploy our expertise into creating technology which delivers good for wider society. We call this tech that matters.

And as our partnership continues, we’ll enjoy the challenges of the ongoing development of Versius alongside scale manufacture, sure in the knowledge we’re developing tech which truly matters.

“There are unquestionably enormous pressures facing public healthcare systems around the world today. These issues are affecting the quality of care being delivered, which we are acutely aware is having a negative impact on patients, their loved ones, and the wider economy. I truly believe CMR’s purpose has never been more important – and I am looking forward to another mission-driven year of making minimal access surgery more widely accessible around the world.”

Per Vegard Nerseth, Chief Executive Officer, CMR Surgical