How collaboration leads Rolls-Royce to advancements in aerospace robotics

Advanced Technology

Automating complex tasks to reduce aircraft engine downtime

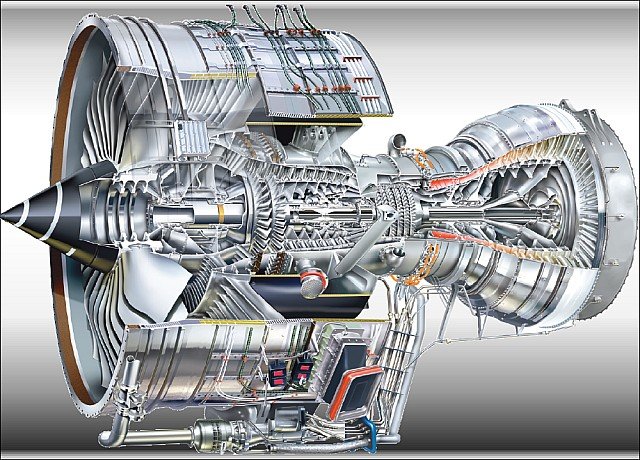

Aircraft engines typically consist of over 20,000 components and necessitate regular servicing due to the critical nature of product quality, cost, and safety. This process demands highly trained specialists and often spans multiple shifts, resulting in substantial engine downtime. Recognising the potential for enhancing operational efficiency through automation in servicing and repair, Rolls Royce initiated a collaboration with the University of Nottingham and Tharsus for an early-stage research project. The objective is to explore how robotics and automation could positively impact on-wing inspections and repairs.

Why collaboration is good for all

Together, Rolls-Royce, the University of Nottingham, and Tharsus have joined forces on a journey to enhance the design of emerging Rolls-Royce aerospace products. With an emphasis on industrialising new technology and implementing it effectively in practical settings, Tharsus has played a pivotal role in supporting Rolls-Royce in this mission.

We take pride in the strong partnerships and trust that has developed between Tharsus, the University of Nottingham, and Rolls-Royce – as a result the collaborative benefits have been profound. Such partnerships yield numerous advantages for all involved parties, ultimately enhancing our collective efforts in supporting Rolls-Royce.

Advantages include:

Access to Expertise

Through collaboration with Rolls-Royce and their highly skilled technicians, we gain invaluable access to specialised knowledge and experience. This expertise can be harnessed to elevate Tharsus’ engineering capabilities, facilitating the development of more sophisticated and high-quality products for all our customers.

Enhanced engineering capabilities

Such a collaborative environment fosters knowledge sharing and growth for all parties. For Tharsus, this results in significant advancements in our own overall UK based engineering

competency, allowing us to tackle increasingly complex projects and deliver innovative solutions to all our customers.

Continuous improvement in the pursuit of excellence

With access to specialist knowledge and skilled technicians, all parties can continuously refine their engineering processes and standards. This relentless pursuit of quality improvement ensures that Tharsus consistently delivers products that meet the exacting standards expected by Rolls-Royce.

An atmosphere of innovation

Collaboration with Rolls-Royce and the University of Nottingham has stimulated a valuable atmosphere of innovation. By collaborating closely with experts in their respective fields, we have cultivated cutting-edge technologies and solutions. This pioneering spirit not only benefits Rolls-Royce but also opens avenues for new technologies and approaches that can

enhance the products and processes of all parties involved.

Greater robotics expertise

Greater robotics expertise has been achieved through collaborative efforts through the pooling of knowledge, skills, and resources. By working closely together, all parties can leverage their diverse backgrounds and experiences to tackle complex challenges head on and push the boundaries of robotics technology.

Furthermore, collaboration enables the development of interdisciplinary solutions that integrate expertise from fields such as engineering, computer science, artificial intelligence,

mathematics and human-computer interaction. By combining diverse perspectives, collaborators can address multifaceted problems more effectively and produce more robust

and adaptable robotic systems.

Conclusion

The collaboration between Tharsus, the University of Nottingham, and Rolls-Royce represents a substantial achievement in the industrialisation of emerging aircraft inspection and repair robotic automation. Together, our focus on continuum robots, modular platform development, and innovative deployment systems has not only advanced the field of robotics but has also brought tangible benefits to not only Rolls-Royce, but also the University of Nottingham and Tharsus.

This successful partnership stands as a testament to the power of collaboration, innovation, and the shared pursuit of excellence in aerospace technology.