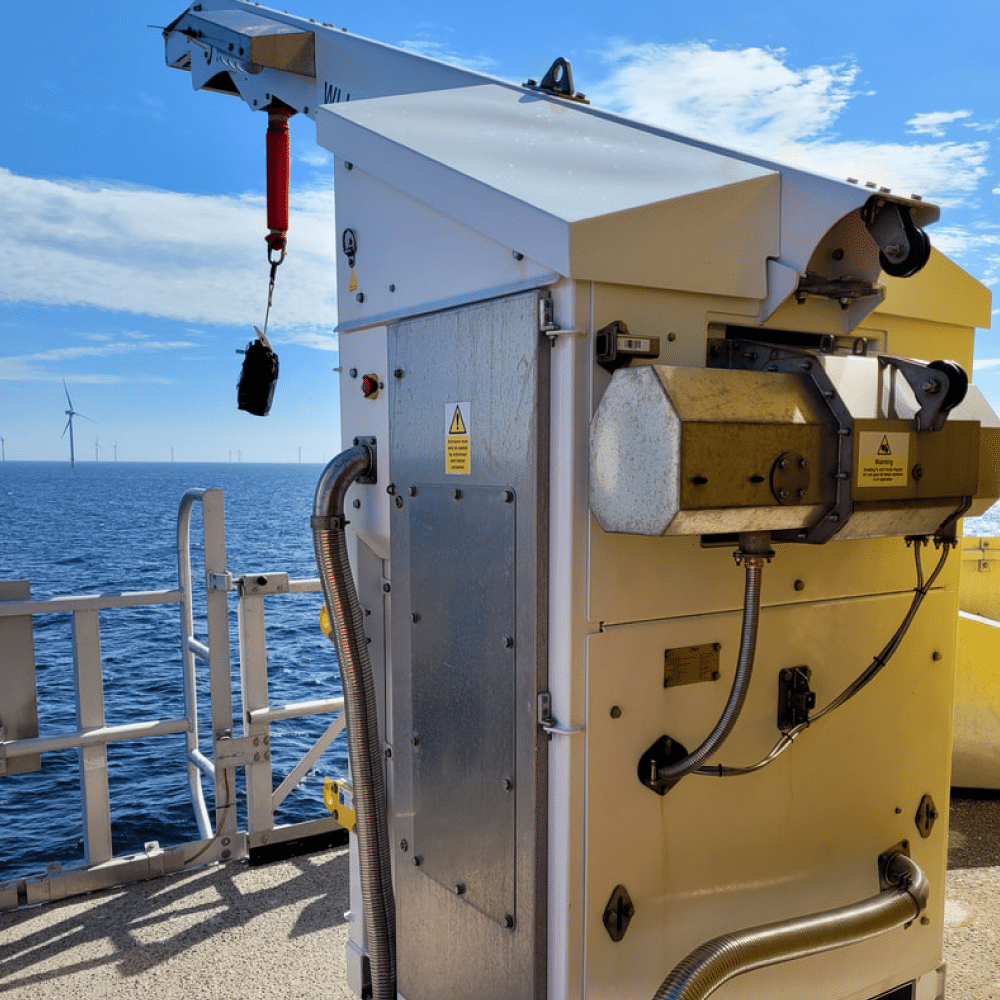

Delivering under pressure. Control cabinet assembly for Pict Offshore’s GUS (Get-Up Safe) system

Electrification and Energy

How Tharsus rapidly onboarded and delivered critical control cabinets for Pict Offshore’s innovative wind access system – GUS.

Project Overview

-

- Client: Pict Offshore

- Sector: Offshore Renewable Energy

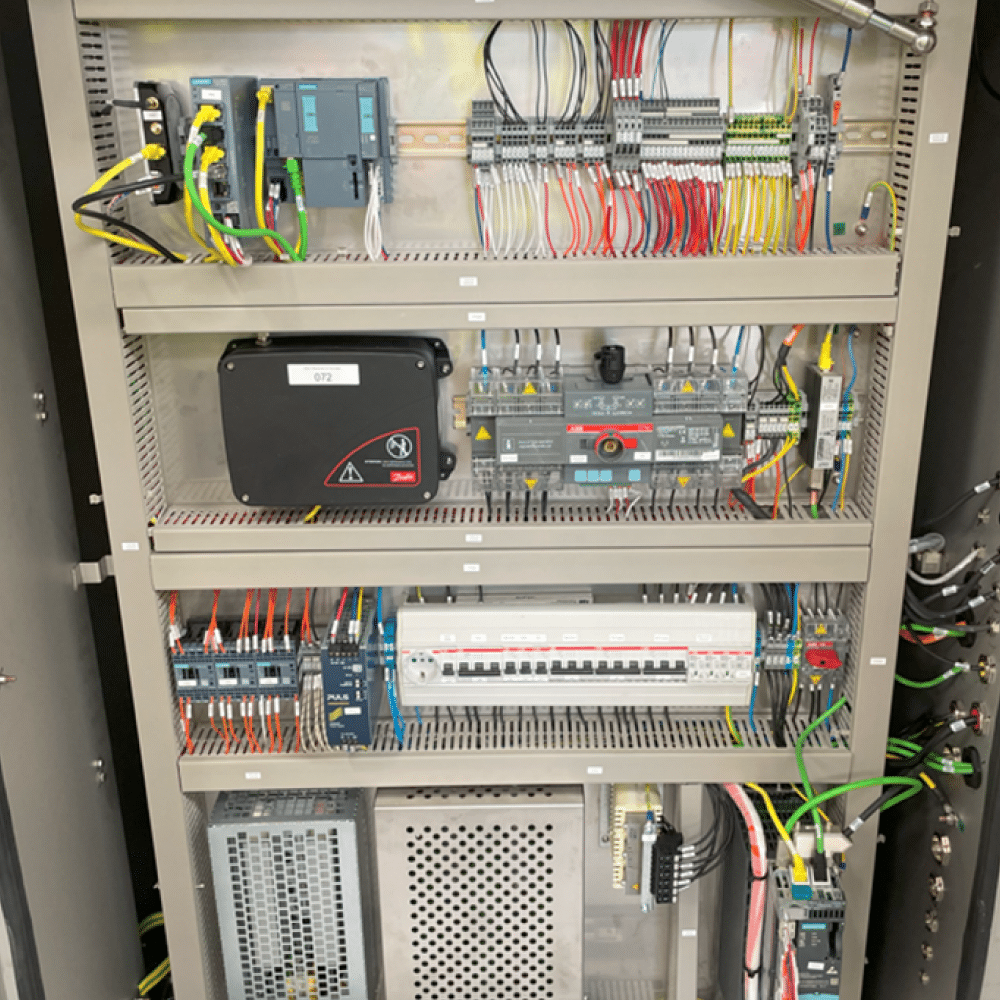

- Project: Control cabinet assembly for GUS (Get-Up Safe) system

- Volume: 20 Units

- Timeline: Accelerated onboarding and delivery

About Pict

Pict Offshore is a Scottish-founded technology company specialising in safer, more cost-efficient access solutions for the offshore wind sector. Evolving from its 2008 roots in indoor climbing safety systems, the company has continually pushed height safety innovation.

Today, Pict Offshore supplies turnkey GUS systems that enable wind farm technicians to transfer quickly, safely, and in rougher conditions than traditional methods from vessels to turbine platforms.

The challenge

Pict Offshore, a technology leader in offshore access solutions, faced a critical supply chain disruption that threatened project timelines for their GUS system. They needed to:

- Rapidly transition to a new manufacturing partner

- Maintain strict quality and safety standards

- Meet original delivery deadlines

- Ensure technical compliance throughout the transition

Our solution

Tharsus implemented a collaborative, cross-functional approach that prioritised transparency:

- Hands-on familiarisation. On-site meetings established a clear understanding and expectations.

- Technical review. Comprehensive technical reviews validated design integrity.

- Supply chain management. Utilised Pict’s existing supply chain, delivering parts to Tharsus and managed within our ERP system

- Documentation transfer. The efficient handover process maintained technical continuity.

- Quality assurance. Rigorous first-article inspections verified performance standards.

- Proactive management. Weekly cross-team coordination addressed potential risks before they impacted delivery.

Results

The partnership delivered all 20 control cabinet units on schedule and to specification, demonstrating how effective collaboration overcomes complex manufacturing challenges:

-

- Zero delays in the project timeline.

- Complete technical compliance.

- Seamless knowledge transfer.

- Foundations built for ongoing partnership.

While contract manufacturing is rarely straightforward, this project came remarkably close. The seamless collaboration demonstrated how a focused, transparent, and technically engaged relationship can drive success, even under pressure.

Why it worked:

- Clear communication channels from day one.

- Shared priorities and aligned objectives.

- Joint problem-solving approach to technical challenges.

- Proactive risk management across both organisations.

This case study demonstrates Tharsus’ ability to rapidly onboard complex technical projects and deliver critical components for the renewable energy sector, maintaining quality and timelines even under significant pressure.