How Tharsus helped Tugbot scale AMR production

Automated Logistics Technology

Scaling innovation by outsourcing production

A strategic manufacturing partnership that’s revolutionising autonomous mobile robotics.

Project Overview

- Customer: Tugbot

- Sector: Automated Logistics Technology

- Product: Tugbot 2 AMR

- Volume: Initial four units scaling to 20+ units

- Market Focus: Europe and Asia

About Tugbot

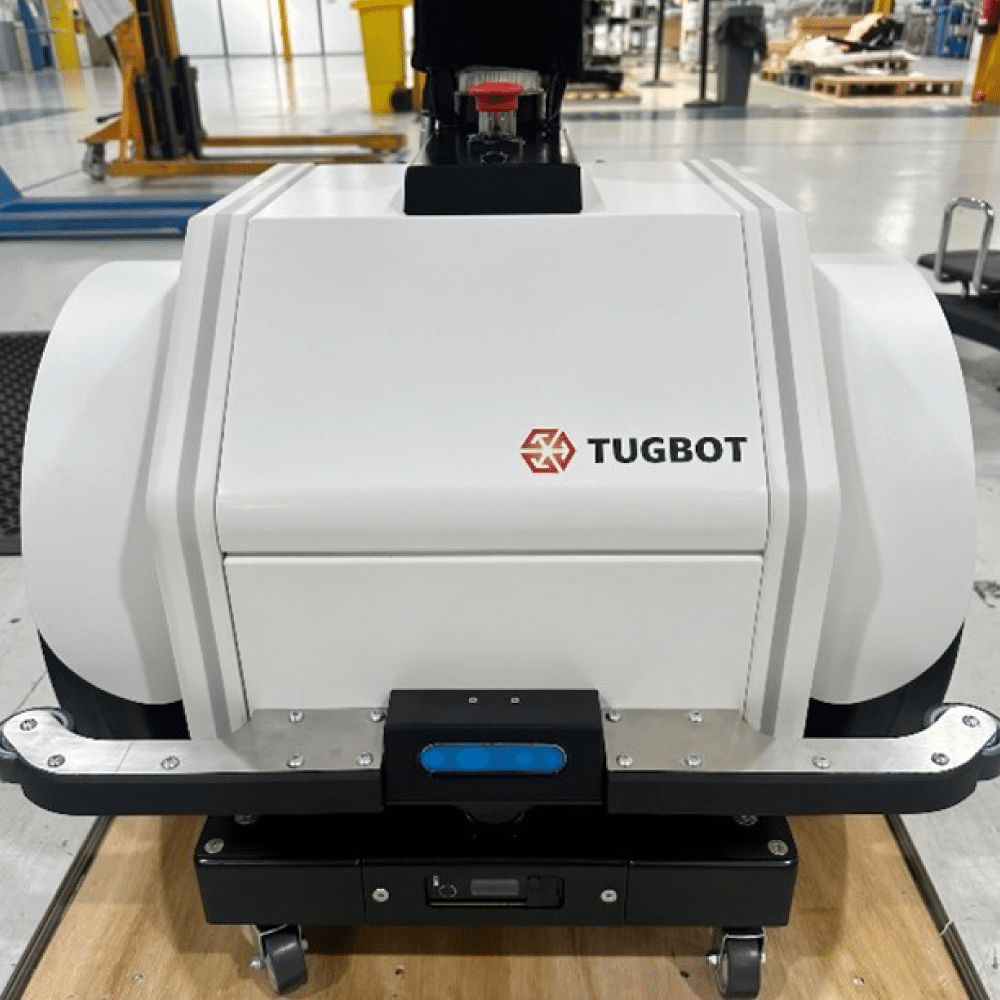

Tugbot, a Portuguese R&D and manufacturing company, specialises in autonomous mobile robots (AMRs) designed to revolutionise intralogistics processes. Their flagship product, Tugbot 2, was initially designed and built in Sintra, Portugal.

Tugbot 2 is a highly innovative Autonomous Mobile Robot (AMR) capable of automating material handling tasks without requiring modifications to facilities or carts. It features advanced capabilities, including wireless charging, natural navigation, and a payload capacity of up to 600 kg.

As their customer base expanded, the company faced increasing demand for its products in Europe and Asia. To meet these volume requirements while maintaining a focus on product development and customer engagement, Tugbot decided to explore outsourced manufacturing solutions.

Tugbot’s challenge

They needed to:

- Scale production capacity beyond in-house capabilities.

- Maintain exceptional quality standards during growth.

- Develop robust supply chains across multiple regions.

- Focus internal resources on R&D and customer relationships.

The technology:

The Tugbot 2 represents next-generation AMRs:

- Versatile operation that automates material handling without facility modifications.

- Advanced capabilities, including natural navigation and wireless charging.

- Industrial-grade performance offers a payload capacity of up to 600kg.

Our approach with Tugbot

Phase 1: Initial collaboration

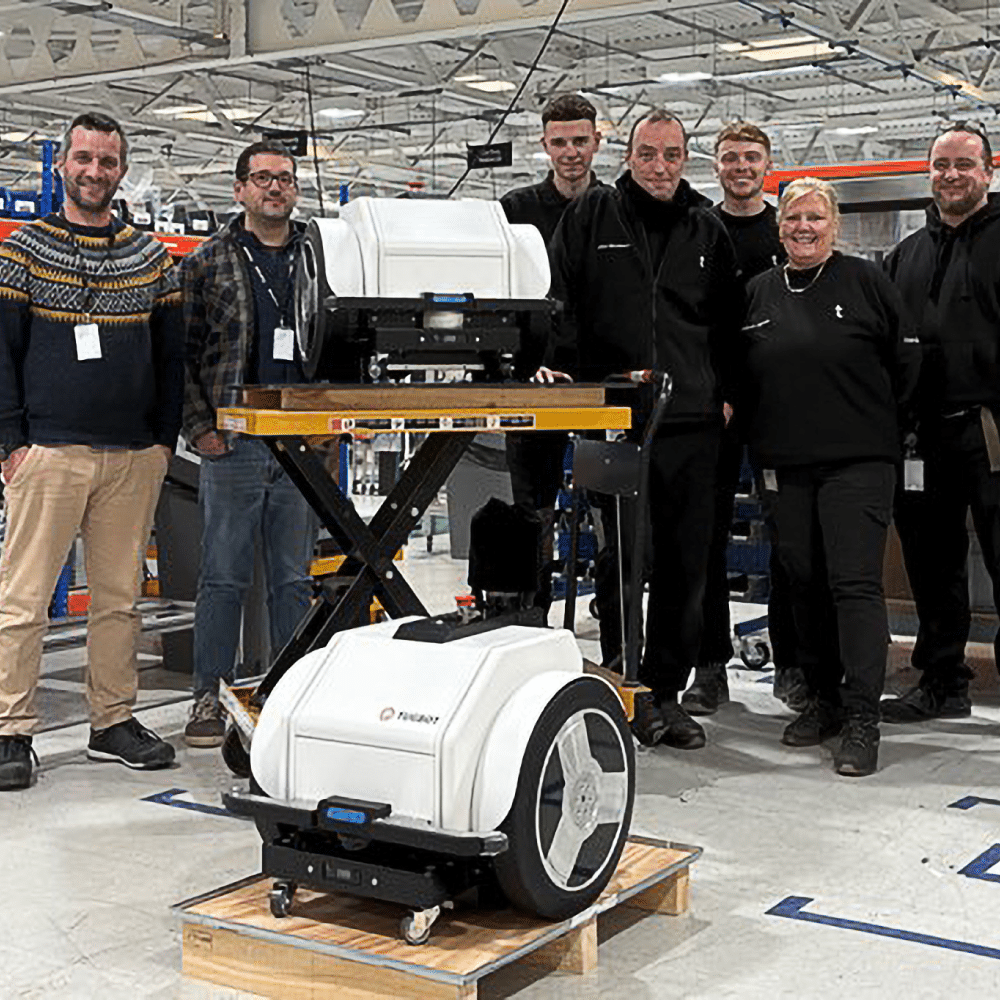

The partnership began in 2024 with Tugbot outsourcing an initial production run of four Tugbot 2 units, establishing:

- Knowledge transfer. Detailed understanding of components, assembly, and testing requirements for the Tugbot 2.

- Local supply chain development. Tharsus leveraged its extensive network to establish a regional supply chain for Tugbot 2 components.

- Manufacturing protocols. Utilising our electromechanical assembly expertise, Tharsus created standardised processes for consistent quality.

- A collaborative framework. Building the relationship model for future scaling.

During this phase, both teams gained valuable insights into the components, design data pack, assembly processes, and testing requirements for Tugbot 2. This iterative learning process was critical for ensuring the product’s readiness for larger-scale manufacturing.

Phase 2: Scaling up production

Building on the success of the initial build, Tugbot and Tharsus transitioned to a second phase involving the production of 20 units to support end-user customers across Europe and Asia.

Tharsus formed a dedicated project team comprising manufacturing engineers, a production team, and experts from supply chain and quality to oversee the development of the manufacturing process, unit assembly, and factory acceptance testing.

Key activities in this phase included:

- Supply chain development. A bespoke sourcing strategy was developed utilising both companies’ unique resources across the UK and the EU to supply parts to Tharsus.

- Quality control. Supplier lead parts inspection and Factory acceptance tests ensured that each unit met stringent performance standards.

- Collaboration. Daily communication via Teams and weekly cross-functional meetings fostered smooth collaboration between Tugbot and Tharsus, ensuring that outcomes prioritised the end users’ customer satisfaction.

Results so far:

The Tharsus–Tugbot partnership is already delivering strategic advantages:

- Scaling production. Tharsus’s expertise is enabling Tugbot to scale output efficiently.

- Quality assurance. Maintained consistent, high-performance standards across all production units.

- Resource optimisation. Freed Tugbot’s internal resources to focus on product innovation and customer engagement.

- Market expansion. Enabled Tugbot to fulfil growing customer demand in key international markets.

Why it works

The success of this manufacturing partnership stems from several critical factors:

- Complementary expertise. Tugbot’s innovative technology, paired with Tharsus’s manufacturing capabilities

- True collaboration. Transparent communication and shared problem-solving

- Scalable processes. An iterative manufacturing approach designed for continued growth

- Customer-centric focus. Mutual commitment to end-user satisfaction

This case study demonstrates Tharsus’s capacity to scale complex robotic technologies from initial production to global deployment, providing strategic manufacturing partnerships that enable innovative companies to meet growing market demands while maintaining focus on their core competencies.

Suppose you want similar success with a collaborative manufacturing partner. Use the ‘Contact Us’ button below to complete our contact form and arrange a discovery call.