Elevating Vertical Farming

AgriTech and Food Distribution

Elevating vertical farming through custom automation for Intelligent Growth Solutions

Intelligent Growth Solutions (IGS), a leading AgriTech company headquartered in Scotland, faced challenges integrating additional automated solutions to their vertical farming operations to boost efficiency, accuracy, and scalability. They partnered with Tharsus to develop a sophisticated automated system to handle propagation trays, integrating seamlessly into existing operations. This case study explores how Tharsus designed an innovative solution to help IGS transform a manual process into a streamlined automated one, setting the stage for future advancements.

Client overview:

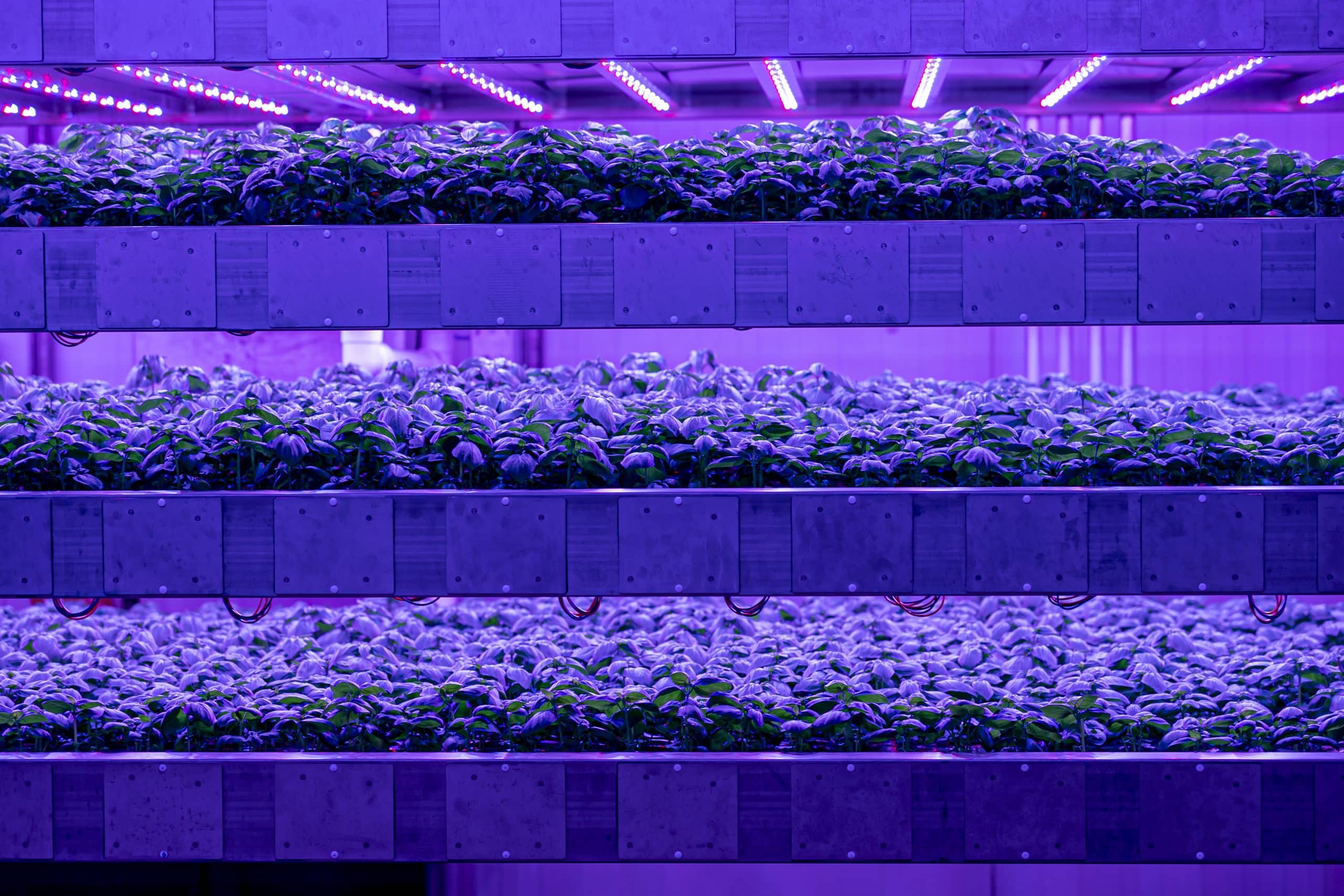

IGS is a pioneering AgriTech company based in Scotland, specialising in advanced vertical farming systems. Founded in 2013, IGS uses cutting-edge technology, including IoT and AI, to create energy-efficient, scalable, and environmentally friendly solutions for modern agriculture, optimising plant growth and resource use in controlled environments.

IGS needed a cutting-edge solution to enhance its vertical farming operations. They turned to Tharsus for a sophisticated automated plant manipulator system that could seamlessly detect and lift propagation trays. The project involved developing a smart detection system and creating an efficient grasper head for handling propagation trays. Additionally, the solution had to integrate smoothly into existing operations, ensuring mechanical compatibility and robust safety standards.

IGS faced challenges in automating its vertical farming operations to boost efficiency and precision. Manual propagation tray handling was slowing their processes and leading to inconsistencies, affecting productivity and growth. They required a sophisticated, automated system to handle propagation trays with precision, enhance efficiency, and minimise downtime. Integrating this advanced technology into their existing setup without disrupting workflow or compromising safety standards was essential. IGS also needed a scalable solution to seamlessly grow with its expanding business while maintaining peak performance and reliability.

Tharsus’s approach:

Understanding the problem

Tharsus began its engagement with Intelligent Growth Solutions (IGS) by conducting in-depth discovery sessions and on-site visits to fully understand the intricacies of IGS’s operations and challenges. These consultations allowed Tharsus to grasp the specific requirements for automating propagation tray handling, cleaning, and integration into IGS’s vertical farming systems. By working closely with IGS, Tharsus identified the critical areas that needed innovation and the unique constraints posed by the existing setup.

Collaborative solution design

Leveraging our Solve + Scale + Supply methodology, Tharsus embarked on designing a tailored solution to meet IGS’s needs. The process was highly collaborative, with continuous feedback loops between Tharsus and IGS to ensure the solution was precisely aligned with operational goals. Tharsus’s engineers worked on creating a sophisticated detection system and a grasper head design for automated propagation tray manipulation. Each component was meticulously designed to integrate seamlessly, enhancing both functionality and ease of use. This collaborative approach ensured that every aspect of the solution was refined to address IGS’s unique challenges effectively.

Solution development

During the development phase, Tharsus utilised advanced technologies and iterative prototyping to refine the automated propagation tray system. Cutting-edge detection systems were developed to accurately identify propagation trays. The grasper head underwent several iterations to perfect its lifting capabilities and ensure durability. Rigorous testing was conducted to validate the performance of each component, ensuring reliability and efficiency in real-world conditions. Sophie, Tharsus’s Design Technical Officer, played a crucial role in overseeing these developments, ensuring the final solution was robustly engineered to integrate into IGS’s existing setup.

Deployment strategy:

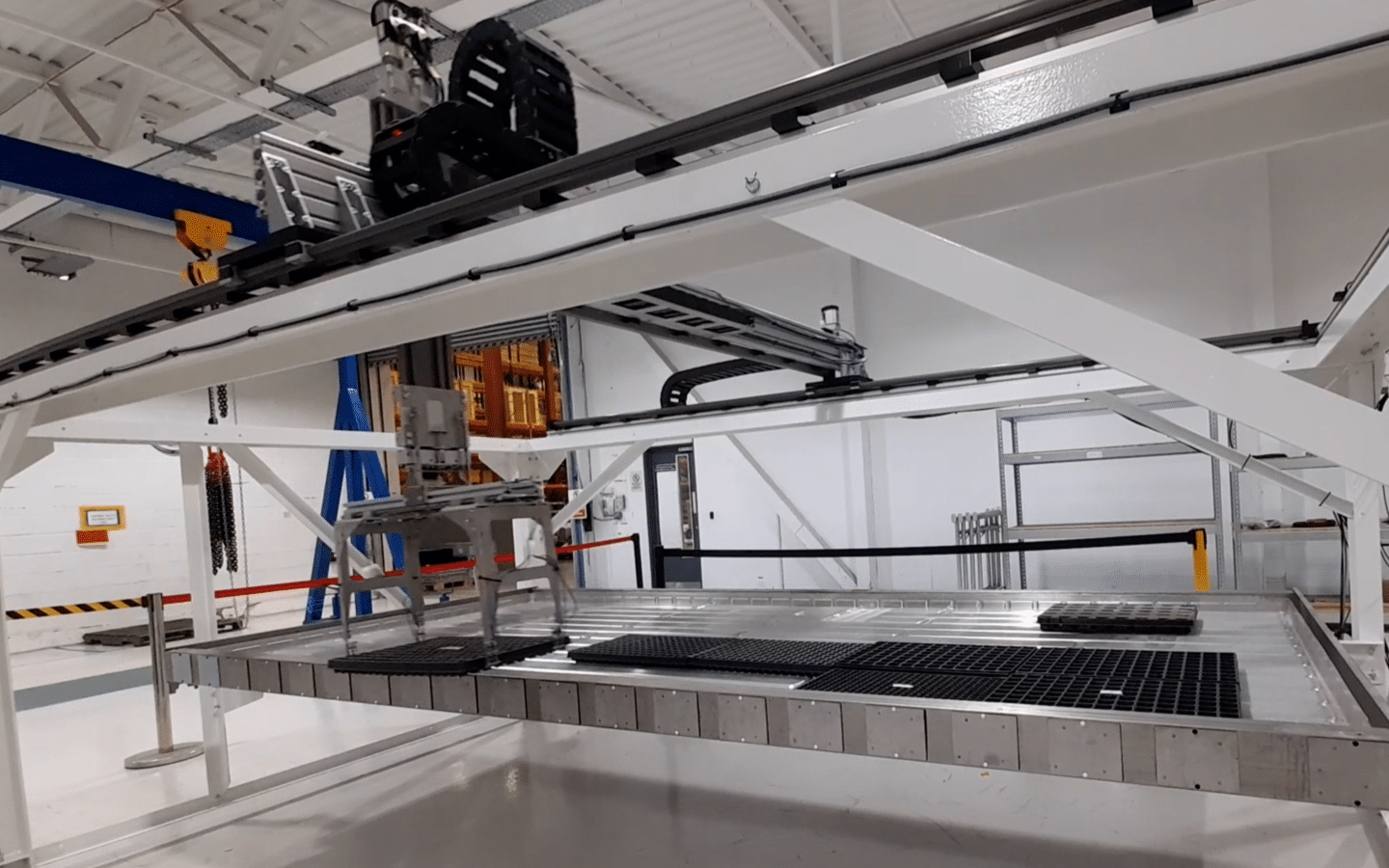

Tharsus executed a strategic implementation plan to ensure the successful deployment of the automated propagation tray system for Intelligent Growth Solutions (IGS). The process began with a mule pilot phase to provide proof of concept ensuring the grasper can sense and pick up the individual propagation trays.

Moving onto a meticulous prototype phase, where Tharsus sourced all components and addressed the challenge of safely constructing a large-scale gantry system. Tharsus completed the build and collaborated with IGS over a dedicated four-day integration visit, which included connecting the customer control system and initial commissioning.

During the test phase, rigorous testing was conducted to validate the grasper mechanism’s effectiveness with various tray types, including the IGS growth tray and liner. Harrison, Tharsus’s recently promoted Graduate Engineer, played a key role in testing the system’s automation capabilities and detection accuracy, particularly focusing on growth tray height and propagation tray manipulation. These tests provided critical insights that informed the next phase of development, ensuring the solution was robust and ready for full-scale roll-out.

Results and impact:

The collaboration between Tharsus and IGS culminated in the successful design and implementation of a functional prototype for their automated propagation tray system. This initial phase has effectively validated the concept, securing further phases of development for IGS’s automated installations. Ongoing testing by IGS, coupled with anticipated collaborative efforts for system optimisation, will continue to enhance the solution. The positive results from this project have paved the way for making the design more robust, setting the stage for the next phase of testing and refinement.

“We are incredibly impressed with the innovative solution Tharsus developed for automating our propagation tray handling process. From the initial consultations to the rigorous testing phases, Tharsus demonstrated a deep understanding of our operational challenges and delivered a system that seamlessly integrates with our existing setup. The collaboration has not only validated the concept but also set a solid foundation for future advancements. Special thanks to Sophie and the entire Tharsus team for their dedication and expertise. We look forward to continuing our partnership and exploring further enhancements.”

Dave Scott, Chief Technology Officer, Intelligent Growth Solutions

Conclusion

Intelligent Growth Solutions (IGS) sought to integrate additional automation into their vertical farming operations to improve efficiency and accuracy, addressing issues related to manual propagation tray handling and integration with existing systems. Tharsus engaged with IGS through discovery sessions and on-site visits to understand their specific needs. They designed a tailored solution featuring a precise detection system and a robust grasper head for propagation tray manipulation. The deployment strategy involved building a large-scale gantry system, comprehensive testing of the grasper mechanism, and successful integration with IGS’s control systems. This collaboration resulted in a functional prototype that validated the automated propagation tray concept, paving the way for further development and optimising IGS’s operations in the vertical farming sector.

Looking ahead, Tharsus and IGS are committed to further refining and expanding the automated propagation tray system. The next phase focuses on making the design more robust, incorporating feedback from ongoing testing to enhance performance and reliability. Tharsus will continue its partnership with IGS, collaborating on system optimisations and exploring opportunities to scale the solution for broader application across IGS’s vertical farming operations. This ongoing collaboration aims to drive continuous improvements and support IGS in achieving its goals of increased efficiency and innovation in the Agri-tech industry.