Expertise

Multi-disciplinary mastery in advanced manufacturing and electro-mechanical assembly

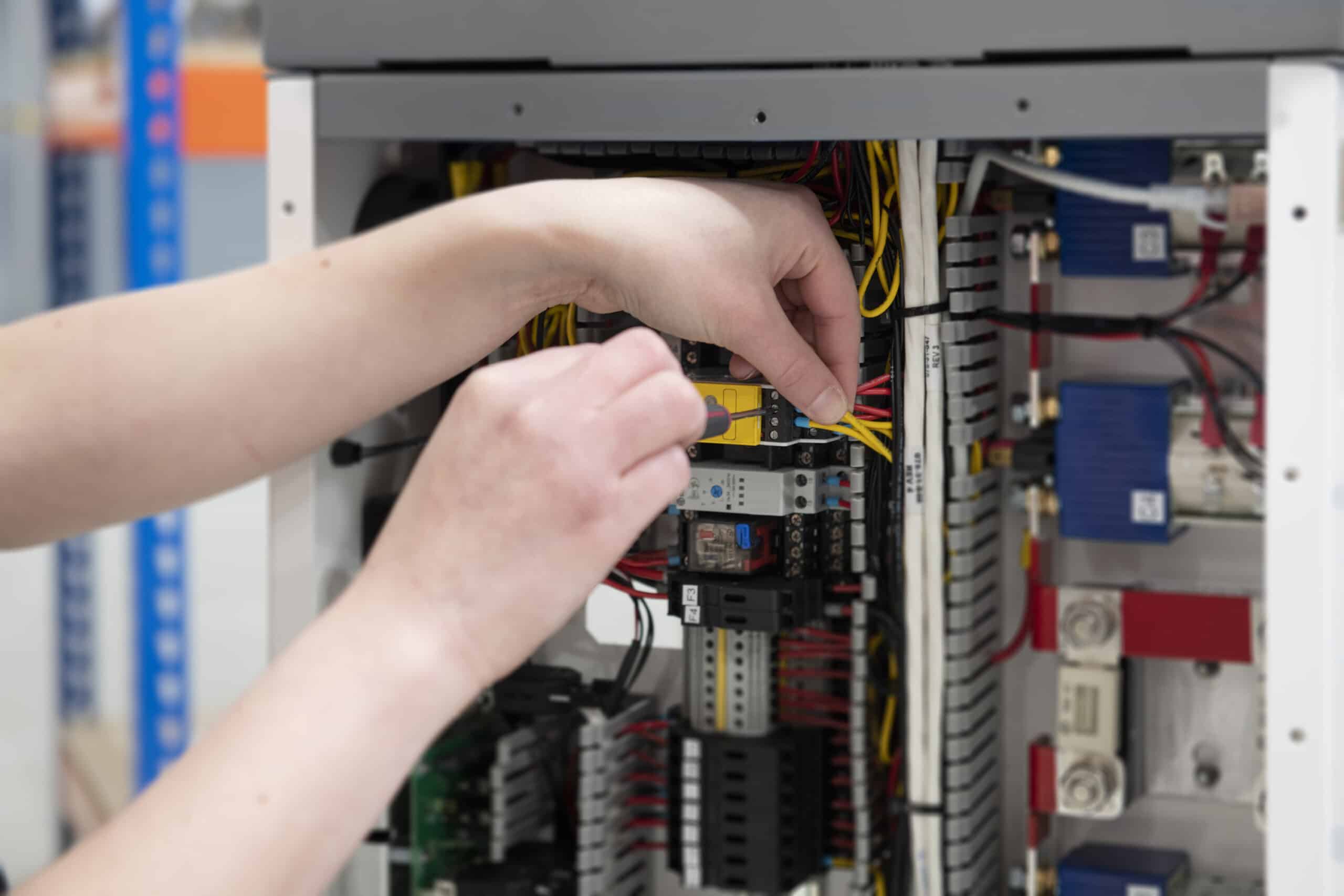

We’re experts in advanced manufacturing and electro-mechanical assembly with deep experience in manufacturing complex tech products.

Many are first of kind, complex tech products. That’s to say products which have never been manufactured before, and need our unique combination of design and manufacturing skills to bring them to market quickly and successfully.

As well as technical excellence, first of kind products require expertise which cannot be taught. Learned through years of first-hand experience, this is essentially the art of avoiding the lethal pitfalls associated with a product’s journey into manufacturing. More mature products also require manufacturing expertise gained from years of manufacturing products accurately and repeatably in large volumes.

Tharsus is unique in that we have the technical expertise and a long track record in contract manufacturing, winning us prestigious industry recognition and long-standing manufacturing partnerships with some of the world’s most important businesses, as well as close collaborations with some of the most exciting new tech businesses around.

Is contract manufacturing right for your business?

One of the biggest decisions our customers face is whether to insource or outsource their manufacturing. Some of the world’s leading businesses like aerospace giant Rolls-Royce, premium car maker BMW and EV charging and Energy Storage System specialist, FreeWire Technologies, have chosen to outsource their manufacturing to Tharsus. With a long track record in contract manufacturing, we wanted to share what we’ve learned over many years of manufacturing complex and first of kind products. As a starting point, it’s useful to ask two questions:

1. Is manufacturing your core business?

In other words, are you a tech business or a manufacturer? If the former, then manufacturing is not your core business activity. So, why would you want to do it? It’s well known that businesses which focus their time and investment on their core competencies are more profitable than those which become distracted by areas outside it.

Instead, why not invest your time and money in your technology? After all, this is where the opportunity for exponential financial success lies. Back in 2012, Ocado took this advice to heart when they appointed us as their manufacturing partner. With time free to focus their energy on developing their tech, they were able to transform from a UK online grocer to a £13 billion global tech giant in a matter of a few years.

2. What is your strategic objective?

If it’s to reap exponential financial reward from your new tech product, you’ll need to go to market quickly and successfully. Until you do, you’re losing money, not making it. And, the longer you leave it, the greater the risk of a competitor beating you to it.

Twelve myths of insourcing vs outsourcing

Tharsus has been at the forefront of excellence in UK Manufacturing since 1964. We’ve delivered outsourced manufacturing for customers in sectors from Agritech to Electrification and Healthcare to Logistics. Probably our biggest learning is how many myths abound about insourcing vs outsourcing.

So, we want to share the twelve biggest myths here and apply some myth-busting best practice:

Is manufacturing your own hardware crucial to success?

#1 Myth: To truly own your tech it’s essential you manufacture it yourself

Reality: As a product owner you’re only as big a business as the success of your product. This means that in the pre-production or early production phase, you’re small. Can you justify the financial burden - not to mention risk - of building your own highly-specialist manufacturing capability at this early stage? Capability which, necessarily, includes CAPEX, the cost of a physical facility to manufacture in, tooling and machinery to manufacture, and a highly skilled team of manufacturing specialists.

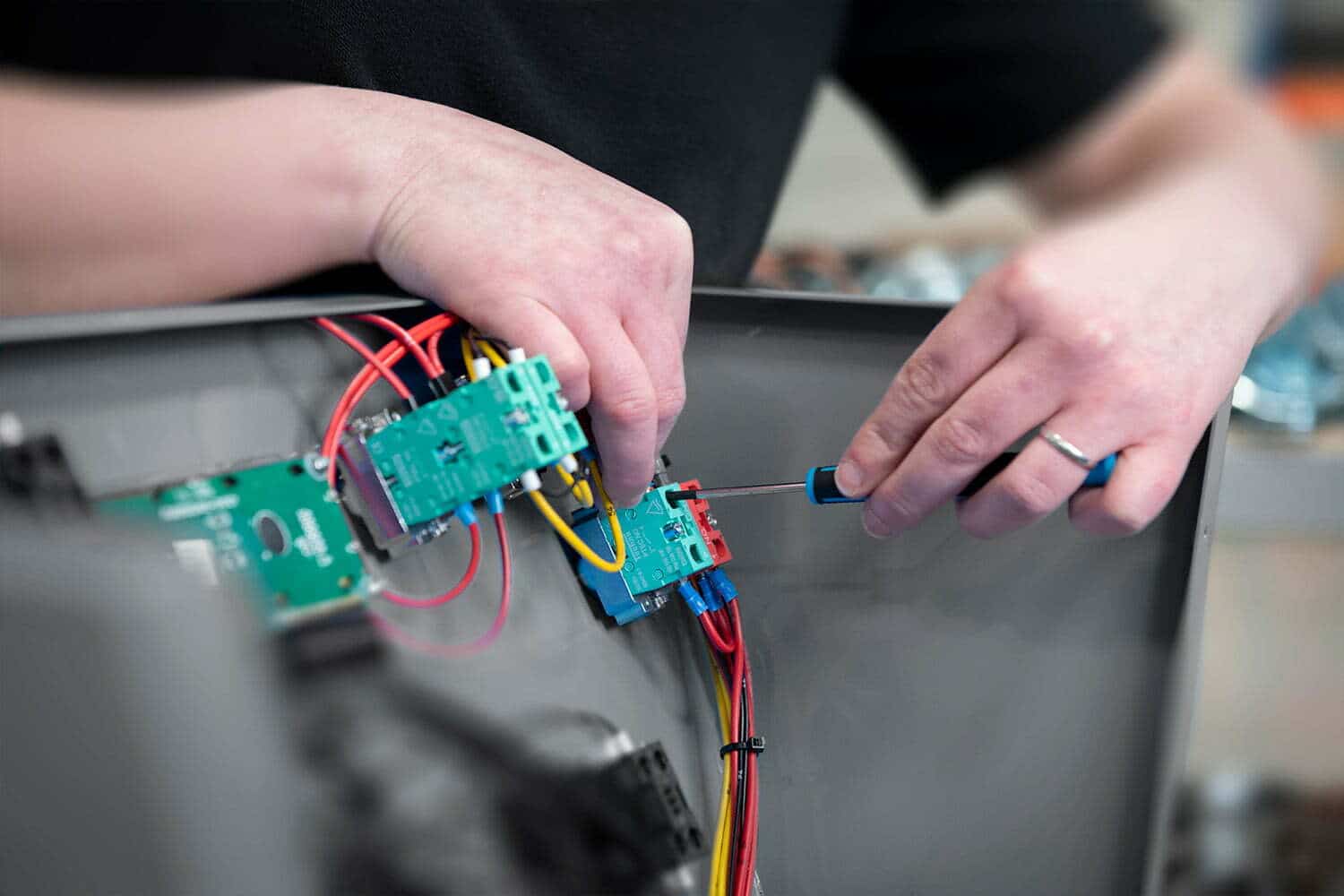

Here at Tharsus, we have a 138-strong multi-disciplinary team of technical experts working in our 99,000 sq ft facility. We deliver accurate successful early and mid-stage Electro-Mechanical assembly and Advanced Manufacturing for some of the world’s leading businesses including Rolls-Royce, FreeWire Technologies and BMW. They see the immense value Tharsus can bring as an outsourced manufacturing partner in de-risking their new tech’s entry to market, allowing them to grow revenue streams far quicker than if they manufactured themselves. Our in-house engineering team resolve issues before they become costly and time-consuming problems.

Doesn’t early-stage manufacture require less labour?

#2 Myth: Manufacturing initial batches can be done with a small team of just 2-3 people.

Reality: Advanced Manufacturing as required by new tech products requires a broad range of skills and capabilities, like Electro-Mechanical assembly, supplier management through secondary and tertiary supply chains, statutory HSE and quality accreditation compliance, product documentation, material control and stock compliance, risk assessments and process audits -- just to scratch the surface. Manufacturing cannot be done properly by a small team.

At Tharsus, we have all the manufacturing expertise with the engineering experience you’ll need to make your product effectively and successfully for you. New customers often come to us with an early-stage product they produced in-house, which couldn’t be properly resolved due to lack of technical or financial resource. We’re able to resolve their product quickly, effectively and at a price point to suit them.

Doesn’t manufacturing inhouse mean you have more control over costs?

#3 Myth: An inhouse team is a fixed cost, so you have complete visibility of spend at all times.

Reality: A team that’s unfamiliar with the complex mix of wants and needs a new product brings can struggle to differentiate and prioritise, so you can easily spend more time on something than is necessary -- causing significant scope creep and financial burden.

A specialist outsourcing manufacturing partner working with multiple customers will necessarily have a highly developed, robust system of time management, as well as a second nature understanding of wants vs needs and how to prioritise activity. This is central to the success of their business, after all. Keep in mind the core premise of an outsourced business is to “achieve more with less.”

Described by customers as “the engineer’s contract manufacturer” Tharsus has deep experience with complex hardware products. Our unique multi-disciplinary team is equally at home taking disruptive new products to market as it is delivering excellence in volume manufacturing.

Isn’t quality better if you insource your manufacturing, rather than outsource it to someone else?

#4 Myth: Isn’t an insourced team closer to the product, and therefore better suited to deal quickly and effectively with quality issues as they arise?

Reality: A highly experienced, specialist outsourced team is far less likely to cause quality issues in the first place. Here at Tharsus, we are engineers and manufacturers that solve problems, so our customers don’t have to.

Quality management is at the core of our commitment to do the right thing, by delivering products and services to our customers with a consistent level of excellence, in compliance with ISO 9001:2015. This is the mechanism by which we bring products to life through our Solve Scale Supply service offering, which means our customers can confidently enter or disrupt markets by delivering from idea or prototype -- all the way to stable volume production.

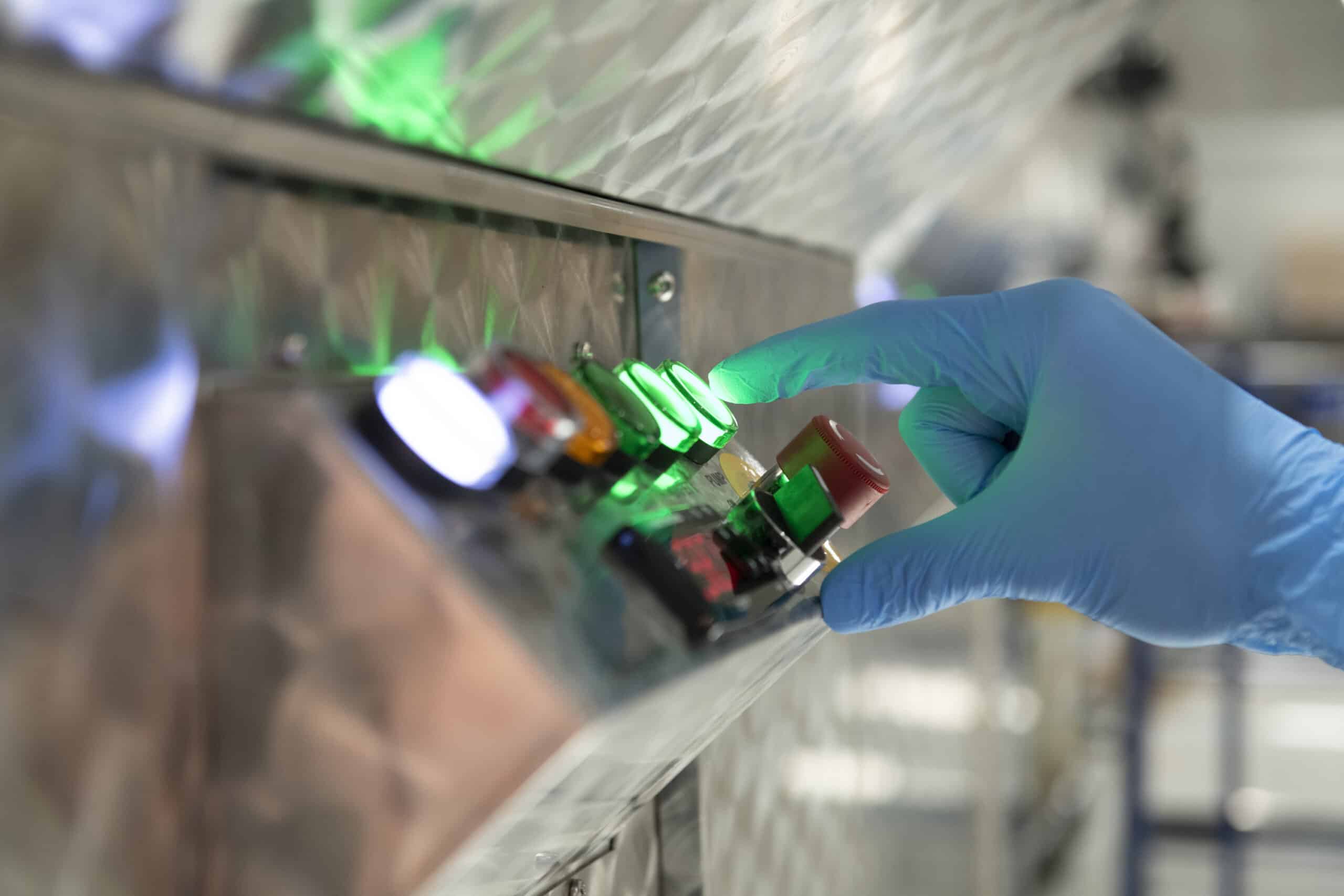

Cambridge Medical Robotics have outsourced their manufacturing to Tharsus for over two years. Surgical robots require the most exacting standards of quality and validation which are far more specialised and go way beyond the competence of most insourced manufacturing teams.

When you outsource your manufacturing, will communication be compromised?

#5 Myth: Members of an insourced team are more proximate and so communicate better.

Reality: Are the members all onsite full time? If not -- and in today’s hybrid world where many aren’t -- then what’s the difference in proximity to an outsourced team? A specialist outsource partner will have invested considerable time and resource to put in place best practice communications with their customers both in terms of channels and structures for project management -- way beyond a flurry of Teams and Zoom calls.

At Tharsus, we have well resolved and understood account management structures and procedures in place which ensure our customers remain front and centre of the work we do for them -- at all times. It is made certain by senior management reviews, challenge, and audit.

Are there additional security risks associated with outsourcing?

#6 Myth: Your confidential information is at risk in the hands of a third-party business.

Reality: Part of the core operational competence of any outsourced business is having robust systems and procedures in place to manage and protect customer data. In contract manufacturing, these are de facto and generally more robust than even a customer’s own.

Our Business Excellence and Digital Technology teams have created one of the most secure integrated data storage and management systems around. This is part of our written commitment to our customers and suppliers -- to promote a total quality structure for the business, ensuring it through management reviews, challenge, audit, and rigorous control of non-conformance.

Does outsourcing put our Intellectual Property (IP) at risk?

#7 Myth: Your IP is super-valuable, so why share it with a third-party manufacturer?

Reality: The value in your IP lies in your product’s effectiveness within its intended market. To realise this value, it needs to get into its market successfully in the first place. This is dependent on you, as its originator, to ensure this happens. Then in turn, it needs to be continually improved and iterated to remain competitive. Only you have the true competence to do this effectively. Your third-party manufacturer’s success relies on this entirely - without you and your IP, they’re going nowhere.

Here at Tharsus, our strength lies in manufacturing tech, not creating it. Back to our “engineer’s contract manufacturer” moniker, our in-house technical expertise makes us great respecters of IP. We are heavily invested in helping to realise and preserve it.

We’ve made, and continue to make, thousands of robots and advanced machines for customers including, BMW, Ocado, Cambridge Medical Robotics and Rolls-Royce while they own - and enjoy the enhancement of – the IP in their products.

Do you miss an opportunity to scale if you outsource your manufacturing?

#8 Myth: Insourcing provides businesses with an opportunity to broaden their core operations through onboarding more diverse skills sets and increased operational scale. Outsourcing denies them this, causing them to miss the boat on what could be a lucrative strategic move.

Reality: In the field of first of kind tech, the product’s speed to market is everything. The longer it takes to get into manufacturing, the greater the risk of a competitor getting to market ahead of you. Building in-house capability is a complex process which takes a lot of time and money. Partnering with a manufacturer at the earliest possible point delivers the double advantage of greater speed to market (and therefore faster commercial return) and early optimisation of your product ready for volume manufacture. Mistakes made in early-stage development tend to be costly and time consuming to fix later on.

As a specialist early-stage manufacturer, we often encourage customers to take manufacturing in-house once their volumes start to exceed our capacity. By this stage, they’ve accumulated enough working capital to comfortably absorb their set up cost -- and enough knowledge from our team to manufacture efficiently in their own right.

Isn’t insourcing your own manufacturing better for your brand image?

#9 Myth: Scaling through insourcing is really good for your brand. Particularly through the employment and upskilling opportunities it brings to people in your local area.

Reality: You're unlikely to find all the skills you'll need within your local area. You’ll be potentially hiring people from outside your region and therefore not providing employment to and feeding into the local economy. That may not necessarily be something you’ll want to shout about.

What you would want to shout about though, is the fact that you’re partnering with a specialist manufacturer, with a global reputation for getting first of kind products successfully into their markets.

Many of our customers actively publicise their relationship with us to validate the robustness of their product to their key stakeholders.

With outsourcing your manufacturing, do you run the risk of a clash of company cultures?

#10 Myth: Your team will clash culturally with an outside team, particularly if you’re both values-led organisations.

Reality: If you’re genuinely values-led, then the value of a successful partnership will be clear to and important for both of you.

Many of our customers are attracted by shared values; in particular, respecting the power of good collaboration with them, with our supply chain and wider stakeholders, to solve the scale and complexity of problems to get new products into manufacture. Greatness is rarely achieved by a solo effort. We understand this very well. Our billing as “the engineer’s contract manufacturer” is recognition of our deep technical and manufacturing expertise – and means we’re effectively thinking as one with our customers on all aspects of their product journey with us.

If you outsource your manufacturing, don’t you put all your eggs in one basket?

#11 Myth: By handing everything to an external partner you place yourself entirely in their hands and lose ownership of the very thing you need to have ownership of.

Reality: Most external partners work closely with project-specific teams within the customers’ own organisations and key decisions are taken collaboratively. It’s this strength of collaboration which provides the momentum that first of kind products need to succeed. Effectively both teams’ goals are aligned. If one wins so does the other.

We have customer teams from Ocado based permanently onsite, while we host teams from US-based FreeWire Technologies for extended visits of up to a month at crucial stages in our manufacturing of their EV Chargers. Meanwhile, extremely stringent quality requirements in medical robotics see the team from CMR make regular trips to check on quality controls – which we’re happy to say we pass with flying colours.

If you outsource your manufacturing, does their financial stability become your risk?

#12 Myth: Using a third-party contractor ties your fortunes to their financial wellbeing.

Reality: Third-party contractors with a strong track record of success are de facto well-funded. You can safely assume they’re a far less risky bet than an immature in-house manufacturing team who may or may not have the skillset required to ensure a successful outcome for your product. As well as the technical skillset to successfully launch your products, they’ll have a clear understanding of the commercial one too, so they – and you -- are in safe financial hands.

Your decision to outsource vs insource your manufacturing is a critical success factor for your product.

In summary, your success as a tech owner is governed by two key factors: getting your new product into the market quickly and getting it into the market successfully. Both require you to manufacture well and manufacture now – and ensure your tech is as good as it possibly can be.

Some of the world’s leading businesses like aerospace giant Rolls-Royce, premium car maker BMW and EV charging and Energy Storage System specialist, FreeWire Technologies, outsource their manufacturing to Tharsus, so they can concentrate on their technology. Whether your product is ready to manufacture and you’re weighing up the pros and cons of taking this on yourself, or you have started manufacturing yourself but are questioning how well it’s working out, we’ll be happy to chat with you about how we can help.

Expertise

Unrivalled technology innovation from a team of specialists working at the leading edge of advanced manufacturing, electro-mechanical assembly and revolutionary ideas.